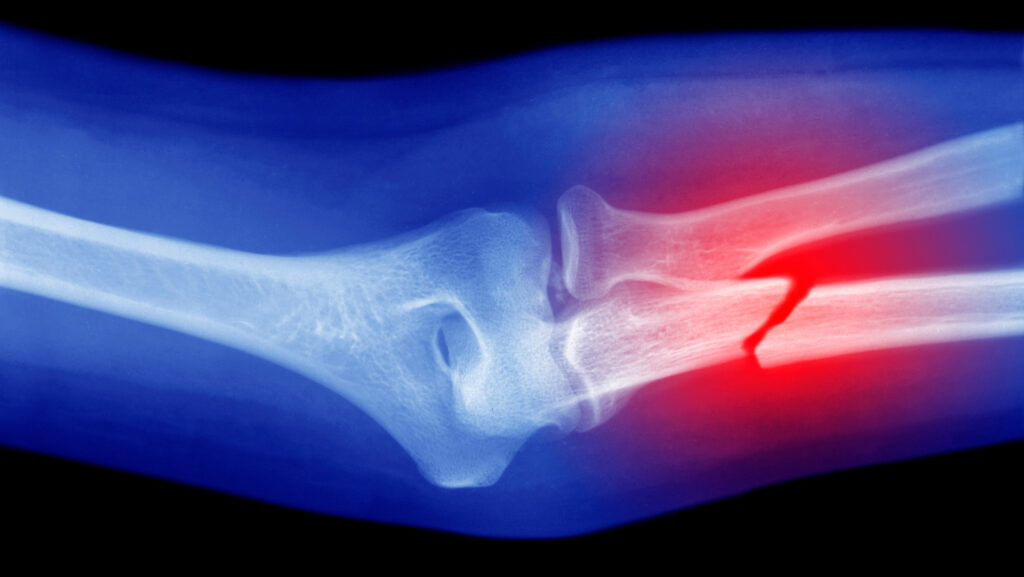

A handheld device can apply synthetic bone grafts directly at the site of a defect or injury without the need for prior imaging or fabrication.

Researchers demonstrated the technology by modifying a hot glue gun to 3-D print the material directly onto bone fractures in rabbits. Instead of using a regular glue stick, they employed a specially made “bioink,” the team reports September 5 in Device.

The idea was to design a printing system that could be easily equipped and used in clinical settings, says biomedical engineer Jung Seung Lee of Sungkyunkwan University in Seoul, South Korea.

“We can save time, cost and complex procedures [compared with those] required in conventional 3-D printing–based bone graft fabrication,” Lee says. Usually, scans and measurements of injuries are needed to build bonelike implants to exact specifications, a process that can take days and delay surgeries.

The bioink consists of two compounds commonly used for 3-D printing implants: hydroxyapatite, which supports bone formation pathways and enhances tissue regeneration, and a biocompatible plastic called polycaprolactone, or PCL, which becomes the scaffold for bone growth.

“PCL is [approved by the U.S. Food and Drug Administration] and gradually degrades in our body over months,” Lee says. “This enables the slow substitution of the graft with the newly grown bone tissue.” The proportions of the two compounds can be adjusted to optimize the material’s strength, stiffness and biochemical properties for each use. The researchers also incorporated antibiotics into the bioink to prevent postoperative infections.

The bioink is simply loaded into the printing device and applied where needed. Because conventional hot glue guns operate at temperatures far too high for living tissues, the researchers modified their prototype to restrict its heat. They also adjusted the tip for better control. Thanks to the low melting point of PCL, the bioink can be applied at about 60 degrees Celsius, cooling to body temperature within 40 seconds. The direction, angle and depth of the device can be tuned during printing, and the whole process takes just a few minutes.

Lee and his colleagues tested the glue gun and bioink on femoral bone fractures in rabbits. Comparing results from rabbits receiving the therapy with a control group receiving regular bone cement, the team found that the former group had better healing and regeneration of bone tissue. The animals also showed no signs of infection during the 12 weeks following surgery.

Lee aims to develop this into a multifunctional printing system, one that has additional substances such as growth factors, antibiotics and other drugs, for use in orthopedic surgeries on humans. At this point, he cautions, this is still a proof of concept. Standardized manufacturing processes, sterilization protocols and further animal studies are all necessary before the technology can make its way to operating rooms.

Deborah Mason, a molecular and cell biologist at Cardiff University in Wales who wasn’t involved in the study, finds the elevated temperature to be a limitation. “The high temperature of the extruded material is likely to stress or kill the cells,” she says.

The researchers are working to modify the tip of the device to make the material’s temperature fall faster right after extrusion.

Nieves Cubo-Mateo, a biomaterials engineer at Nebrija University in Madrid, says that this device has the potential to evolve into a “bone printer pen” for surgeons. But there is a long way to go for that to happen, she says. For example, Lee’s printer must be compatible with imaging technologies and robotic assistance used during surgeries. That would make this device “not just a defect-filler but a genuine regenerative tool adaptable to different surgical specialties.”

Read the full article here